Biotech Medical Industry requires high standards for quality and regulations. WJP has been achieving medical packaging over the years by design and manufacture. The tray is made of medical grade PET material and the top is sealed with Tyvek. It allows the packaging to pass EO or Gamma sterilization. This packaging helps protect the glass tube from transportation impact and keeps the product clean and sterile.

WJP has years of experience in packaging design. Including research and development in the packaging quality for biotech and medical industry, which can help clients manufacture packaging materials that meet high medical registration requirements.

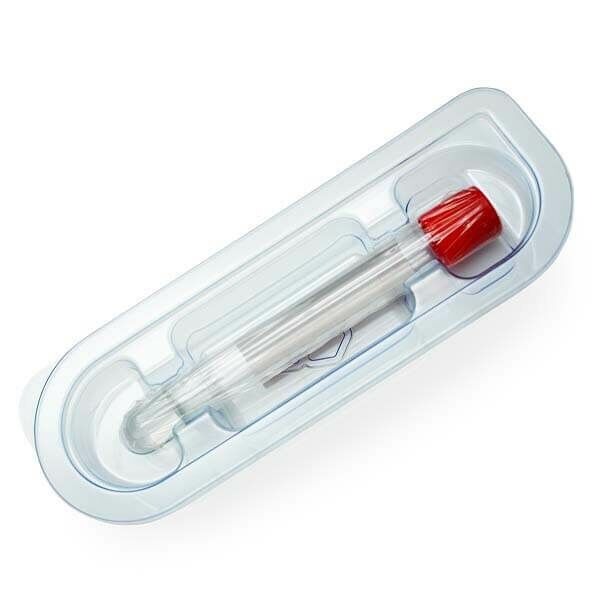

Single glass test tube safety packaging:

The packaging is rounded and easy to grip, without sharp edges. The glass tube clip structure securely holds the glass tube body, making it easy to insert and preventing it from falling even when turned upside down. However, the delicately shaped tube cavity is designed for easy removal even when wearing gloves.

The plastic blister has a buffer space below the cavity of the test tube, which raises the body of the glass tube to avoid collision damage. The bottom of the plastic blister is flat and easy to place, allowing the operator to place it securely without worrying about shaking or rolling.

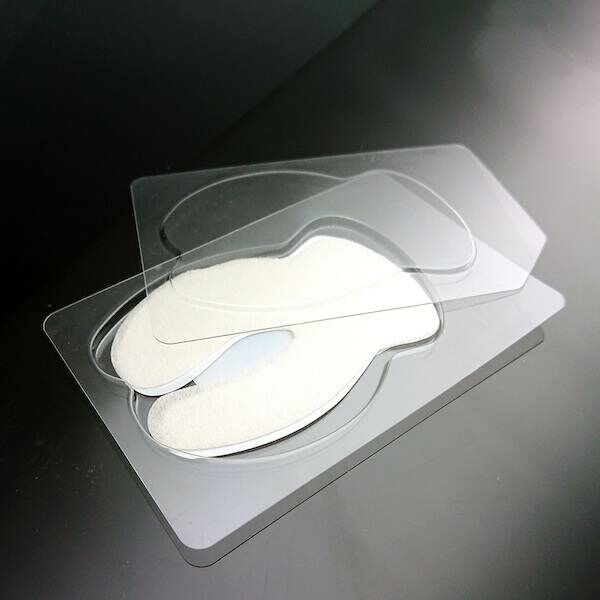

Tyvek paper heat-sealed cover:

This set of medical-grade PET plastic blister has a protruding edge at the sealing joint, which enhances the smoothness and adhesion of Tyvek paper during bonding, and strengthens the sealing effect with Tyvek paper. The lower left side is designed with a tear-off opening, which is easy to tear off by hand and easy to grip with higien gloves. This packaging design can pass Gamma & EO sterilization and protect the internal glass test tube from impact during transportation while maintaining a clean and sterile environment inside.