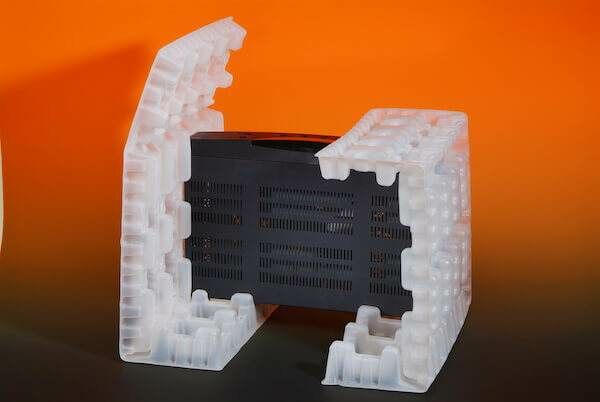

To reduce space and decrease shipping cost, HPDE material is used instead of PU material. For this case, two- sided buffering packaging can carry 12kgs and can pass drop tests. By design and material properties, WJP team offers the best solutions while saving on the shipping cost.

Packaging cushioning can carry 12kgs while pass drop tests. To cut down on space and shipping cost, HPDE comes in handy as the replacement of PU material. In this case, two- sided buffering packaging can carry 12kgs which also pass drop tests. By design and material properties, WJP team offers the best solutions while saving on the shipping cost.

Packaging Less, Protect More

Stuffing materials are taken as the buffering for packagings for decades. Most people need to put layer and layer of air wrap on thier product before they are sent on the delivery truck. However, the fact is, air bubbles are too big for delivery, and too light for recycle. The extra volume result of the air bubbles is not only cost more delivery fee, but also cause more time and fossil fuel for the extra freight trains.

Why Use WJP’s Packaging Cushioning

WJP’s Packaging Cushioning design helps products build the firmest structure in the very beginning. After packed, sensetive devices or fragile content are equipped with resistance to mechanical shocks.

Handy for Multiple Selling Channal

In response to the variety of consumer shopping habits online and offline, packaging that can stand long distance transportation has become necessary. WJP’s strong packaging design will help your product stand out and adapted any sales channel.